Synergy's Moulds empower you to adapt your production line to the ever-changing market landscape. Our experts will work alongside you to implement new formats and SKUs efficiently and effectively, helping you optimize your machine/line's productivity and performance. Elevate your packaging capabilities and stay ahead of the curve with Synergy's brilliant support.

Original Synergy moulds

The full range of Synergy moulds is engineered for any demanding production speeds and is thoroughly tested to ensure the quality of your PET containers. With decades of PET packaging expertise, we can support you at every step of your new container project, from packaging engineering to moulds and parts delivery.

Our state-of-the-art Mould, Line Conversion and Packaging Center in India produces over 3000 moulds annually, ensuring we can rapidly respond to your evolving packaging needs globally.

Synergy Packaging designer team can also support you in engineering the right PET container for your product. Learn more about our packaging capabilities >

Certified fit and function

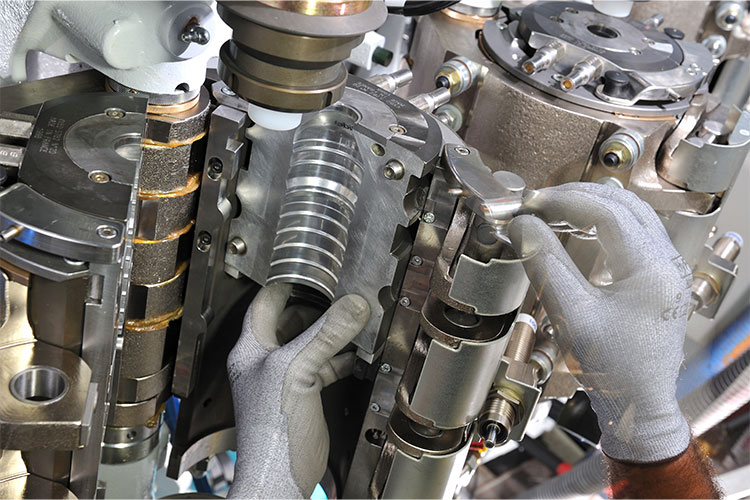

All our original moulds are produced by Synergy experts, who carefully provide customer solutions that keep performing over time:

- Optimal material and treatment combinations

- OEM production standards and quality

- High accuracy control

All moulds are certified for maximum uptime and are warrantied to last.

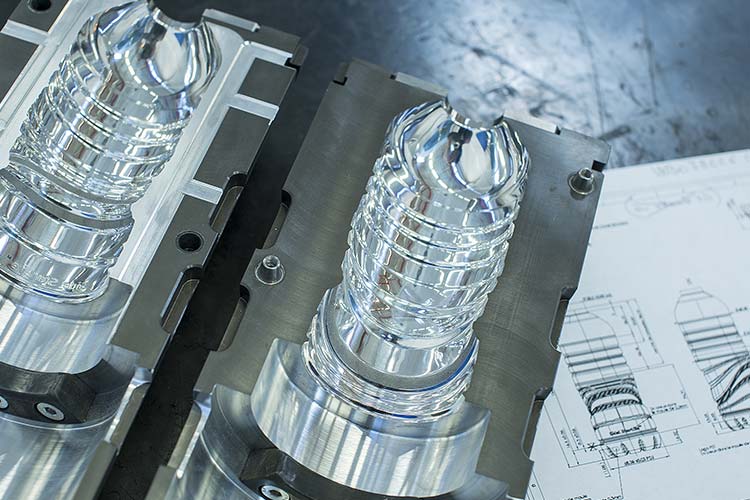

A mould for every container

Each project is different. Synergy engineers design unique moulds that can fit with any type of blower and blowing process. The 500,000+ moulds sold over the last 20 years attest to mould expertise that can optimally address your container project:

- Vast freedom of PET-container shape and texture with multiple technologies

- Wide range of PET container size, offering numerous options and possibilities

- High safety and product quality

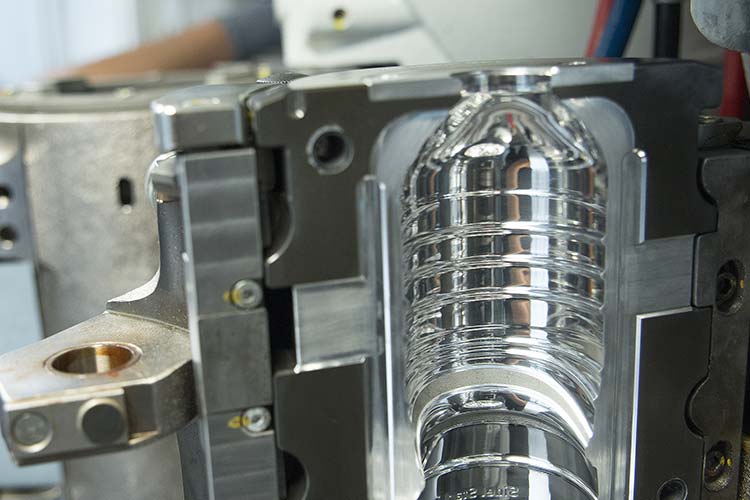

Extended mould and parts lifecycle to maintain production performance

Regardless of the generation of your blower, you can maintain performance thanks to our mould and parts regeneration services:

- Mould and parts replacement with brand-new ones

- Mould and parts repair

- Mould and parts refurbishment at OEM standards